Ever thought about how, in the busy world of software development, we might sometimes forget to keep track of important know-how as our code gets bigger and teams change? Well, maintaining a clear understanding of our codebase is crucial to ensure the longevity and efficiency of our software projects.

Enter the Operation & Maintenance (O&M) Manual – an often overlooked, yet critical document, that bridges the gap between complex software processes and those responsible for them.

Just as hardware and machinery industries have benefited immensely from clear O&M documentation, software companies stand to gain from well-structured, comprehensive guides. Beyond merely a manual, this venture taps into the broader spectrum of knowledge management, ensuring that information, experience, and expertise are preserved, accessible, and easily transferable.

In this article, we’ll dive deep into crafting an O&M Manual that not only serves its primary purpose but also positions your software firm at the forefront of efficient knowledge preservation and sharing.

The Purpose of an O&M Manual

While many might simply consider an O&M manual as a supplementary document that comes with a piece of product or a system, its true significance runs much deeper. Let's explore the fundamental reasons behind the existence of these manuals and the benefits they bring.

First, let's look at what an O&M manual is.

What is an Operation & Maintenance Manual

An Operation and Maintenance Manual, often abbreviated as an O&M manual, is an exhaustive resource offering detailed guidance on the operation, maintenance, and troubleshooting of a particular product or system.

Unlike user guides, which might focus primarily on basic usage, or installation manuals that target the setup phase, O&M manuals are exhaustive resources. They cover everything from the basic functionalities to intricate maintenance routines, ensuring a holistic understanding for the user.

The Purpose of O&M Manuals

To fully understand the purpose of O&M Manuals, we have to look at the benefits these crucial documents provide. Let's explore the numerous advantages an O&M manual offers, highlighting its essential role in optimizing software and operational procedures.

- Efficient Operation: A well-structured O&M manual ensures that product users have all the necessary knowledge at their fingertips. This results in optimal utilization of the product, reducing the risk of mishandling or operational inefficiencies.

- Prolonging Product Lifespan: Regular maintenance is key to extending the life of any product. With clear maintenance instructions and schedules, O&M manuals ensure that the product continues to function efficiently for a longer period, thereby reducing the frequency of replacements and repairs.

- Reducing Operation Costs: The U.S. Department of Energy states that proper maintenance practices can result in up to 30% reduction in operation and maintenance costs for various systems and equipment. Mistakes in operation or delayed maintenance can lead to expensive repairs or even replacements. By adhering to the guidelines in the O&M manual, businesses can minimize these unforeseen expenses.

- Ensuring Safety: Perhaps the most crucial benefit of all. O&M manuals often come with safety guidelines that prevent accidents or mishaps. By following these guidelines, operators can ensure not only their safety but also the safety of those around them.

In essence, an O&M manual serves as the backbone for the optimal functioning of any product or system. It's not just a 'nice-to-have'; it's an absolute necessity for businesses and operators who want to ensure safety, efficiency, and longevity in their operations.

Key Components of an O&M Manual

After delving into the benefits of an O&M manual, let's break down its structure. To craft a manual that genuinely serves its users, one must understand its key elements. A good O&M manual is comprehensive, clear, and well-organized.

Here are the essential components that make an O&M manual truly effective:

1. Product or Equipment Description

At the heart of every O&M manual is the detailed description of the product. This section provides:

- Technical Specifications: From dimensions to power requirements, this area offers a quick snapshot of the product’s technical attributes.

- Functional Overview: This gives readers a comprehensive understanding of what the product does and its primary functions. It's like the product’s story – its purpose, capabilities, and features.

2. Operational Instructions

Operators turn to the manual primarily for this. Detailed, step-by-step guidance on:

- Startup Procedures: Instructions on how to get the product up and running from a state of rest.

- Operating Procedures: Guidelines on everyday operation, ensuring optimal performance and safety.

- Shutdown Procedures: Steps to safely and efficiently power down the equipment or system.

3. Maintenance Procedures

Ensuring the longevity and optimal functioning of the equipment relies on this section:

- Routine Maintenance: Details on regular check-ups, update procedures, and other essential tasks to keep the equipment in top shape.

- Troubleshooting Common Issues: A list of potential problems, their symptoms, and solutions. This section is a lifesaver when things don't go as planned.

- Replacement of Parts: Instructions on when and how to replace worn-out or damaged parts, ensuring the equipment remains functional.

4. Safety Guidelines

Safety can never be overemphasized. This section provides:

- Precautionary Measures: Tips and guidelines to prevent accidents and ensure the safe operation of the equipment.

- Emergency Procedures: Clear steps to be taken in case of unforeseen issues or emergencies, helping to prevent harm and minimize damage.

5. Illustrations and Diagrams

A picture is worth a thousand words. Including visual aids can:

- Enhance Understanding: Detailed diagrams and illustrations can clarify complex procedures or parts, making the manual more user-friendly.

- Provide Visual Reference: Images of parts, especially in the troubleshooting section, can help operators quickly identify and address issues.

6. Standard Operating Procedures (SOPs)

A critical addition, SOPs provide:

Step-by-Step Protocols: Documented procedures for critical and routine operations, ensuring consistency and adherence to best practices.

Quality and Compliance Assurance: Ensuring that operations meet industry standards and regulatory requirements.

7. Glossary and Terms

To ensure everyone's on the same page, a glossary is crucial:

- Defining Technical Terms: Not everyone reading the manual will be familiar with all technical jargon. Providing clear definitions ensures clarity for all readers.

By incorporating all these components, an O&M manual can serve as a comprehensive guide, ensuring that operators and technicians have all the knowledge they need for safe and efficient operation and maintenance.

The Step-by-Step Guide to Crafting Your O&M Manual

Creating a comprehensive and effective O&M manual isn't just about jotting down procedures and specifications. It's a meticulous process, one that requires precision, clarity, and a deep understanding of the equipment or system in question.

As we venture into the core of this guide, you'll be equipped with a structured approach to gather relevant information, design, format, and update your manual. Let’s get down to it.

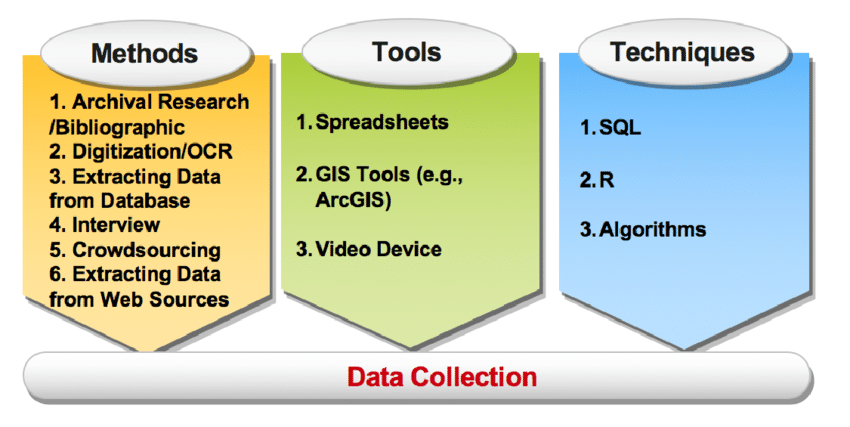

Step 1: Collecting Information for the Manual

Before you can put pen to paper, or fingers to keyboard, you must first arm yourself with all the necessary data and insights. The quality of an O&M manual heavily relies on the accuracy and comprehensiveness of the information it contains.

Here's how to go about collecting this crucial data:

Consult Engineers & Technicians

Before diving into the writing process, ensure you're equipped with all the vital data and insights. A top-notch O&M manual hinges on the precision and depth of the information it encompasses. Here's your action plan for gathering this essential data:

- Value of Expert Input: Your technical team holds a wealth of knowledge. They understand the equipment's nuances and offer key insights into its operation and maintenance.

- Tap into Hands-on Experience: Those who work with the equipment daily offer insights that can reveal routine challenges, effective practices, and undocumented tips.

Seek User Feedback

Engage end-users and those who often refer to the manual to understand its practical usability and potential areas of enhancement.

- Utilize Real-World Insights: Users are the definitive testers of any manual. Collect feedback from those who've navigated previous manual versions or from operators who've operated without one. Their insights can unveil missing info, unclear sections, and potential enhancements.

- Refine Based on Feedback: A relevant O&M manual evolves. Continuously integrating user insights ensures your manual stays current and user-centric.

Use Manufacturer's Documentation

Leverage official documentation and guidelines provided by equipment manufacturers to ensure technical accuracy and compliance.

Draw from Original Equipment Data: Manufacturers typically offer in-depth equipment documentation. This is invaluable, especially for technical specifications and suggested maintenance routines.

Incorporate Manufacturer Guidelines: Manufacturers set specific best practices for their devices. Integrating these not only ensures optimal performance but can also preserve warranty conditions.

With data from these avenues, you're set to craft your O&M manual. The depth of your groundwork will directly reflect in the manual's efficacy and breadth.

Step 2: Organizing and Structuring the Manual

Having collected a plethora of valuable information for your O&M manual, the next challenge is arranging it in a manner that’s intuitive, user-friendly, and efficient. A well-structured manual isn’t just about content; it’s about delivering that content in a way that enhances comprehension and ease of use.

Let’s break down the steps to achieve this:

1. Set the Flow

Every great story has a beginning, middle, and end. Similarly, your manual should have a logical sequence. Start with a general overview of the equipment or system, move to detailed operational instructions, and then delve into maintenance and troubleshooting procedures.

By leading your readers progressively deeper into the nuances of the equipment, you ensure they build a solid foundational understanding before tackling more complex topics.

2. Ensure Quick Access

The best manual is one that lets users quickly find what they're looking for. Incorporate elements like:

- A detailed table of contents at the beginning.

- An index at the end for quick reference.

- Tabs or color-coded sections for major topics.

This ensures that whether a user is reading sequentially or seeking a specific piece of information, they can get to it swiftly.

3. Group Related Data

Clump together related data to avoid overwhelming the reader. Create sections like:

- Operational guidelines.

- Routine maintenance schedules.

- Troubleshooting techniques and solutions.

Within these sections, use subheadings and bullet points to further break down information and enhance readability.

4. Add Visual Aids

Visual aids can dramatically improve comprehension, especially for complex procedures or intricate equipment parts. Strategically place:

- Diagrams that detail the inner workings of the equipment.

- Step-by-step illustrations for processes.

- Photos of the equipment from various angles or highlighting specific components.

Remember, a well-placed visual can often convey information more efficiently than paragraphs of text.

5. Emphasize Crucial Points

Safety warnings, crucial operational steps, or time-sensitive maintenance tasks must stand out. Use design techniques like:

- Bold or colored text.

- Iconography, such as exclamation marks for warnings.

- Boxes or sidebars to segregate critical data.

By ensuring that vital information is immediately recognizable, you add an extra layer of safety and clarity to your manual.

6. Maintain Uniformity

Maintain a uniform style throughout. Whether it’s the font, the way you present steps, or the icons you use. Keeping things consistent ensures enhanced readability and reduced chances of misunderstandings or confusion.

Consider creating a style guide or template at the beginning. This can serve as a reference, ensuring that the entire manual maintains a consistent look and feel.

In summary, while the content of your O&M manual is undoubtedly crucial, the way you present that content can significantly impact its effectiveness. With a structured, organized, and well-designed manual, you empower users to operate and maintain their equipment confidently and safely.

Step 3: Drafting and Writing the Content

The heart of your O&M manual lies in its content. While collecting data and structuring the manual are crucial preliminaries, the way you articulate this information will determine its utility and clarity. Drafting a manual requires a balance between precision and accessibility. Here's how to ensure your content hits the mark:

1. Choose Clear Language and Tone:

Precision is paramount in an O&M manual, but that doesn't mean the language should be complex or jargon-heavy. Aim for:

Clear Language: Use straightforward terminology. When technical terms are unavoidable, ensure they're explained or provide a glossary.

Consistent Tone: Maintain a professional tone that’s also approachable. You're guiding users, not lecturing them.

2. Describe with Precision

Every procedure or description should be thorough. However, avoid being verbose. The goal is to:

Detail every step or procedure clearly.

Stay concise. Avoid intimidating long paragraphs.

Lengthy paragraphs can be intimidating and may deter readers.

3. Use Active Voice

Active voice lends clarity and immediacy to your instructions. For instance, "Press the button" is more direct than "The button should be pressed." Using active voice:

Makes instructions more straightforward.

Reduces the chance of misunderstandings.

4. Seek and Incorporate Feedback

Your draft can greatly benefit from diverse perspectives. Before finalizing:

Engage Technicians & Engineers: Their hands-on experience can spot technical inaccuracies or suggest clearer phrasing.

Gather End-User Opinions: Users can provide insights into the manual's usability and clarity. Their feedback can be invaluable in refining your content.

5. Do Revisions Regularly

Writing an effective manual is an iterative process. Don't hesitate to:

Revisit sections to refine the language.

Reorder content for better flow and clarity.

Continuously improve upon feedback and self-review.

6. Proofread

Once you're satisfied with the content:

Thoroughly review for grammatical or spelling errors.

Check for consistency in terminology and formatting.

Consider employing a professional proofreader or editor. They can bring an unbiased eye to your work and ensure its polished to perfection.

In a nutshell: Crafting your manual is more than just listing procedures. Prioritize technical correctness while keeping content digestible. With diligence, feedback, and iterative refinement, your O&M manual will be indispensable to its users.

Step 4: Finalizing and Distribution

As you near the completion of your O&M manual, the final touches can greatly influence its usability and longevity. The manual's presentation, distribution, and adaptability can either make it an invaluable asset or reduce its effectiveness.

Source

Here’s how to ensure your manual remains a pivotal resource for its users:

1. Layout and Design

The heart of the manual might be its content, but don't underestimate the power of a well-designed layout. It's not just about making it look good – the right design can make your manual far easier to read and understand.

Thinking of leveling up the manual's look? Consider hiring a graphic designer. They have the skills to take your content and turn it into a visually striking yet organized masterpiece. And when you're picking fonts or deciding on a layout, always keep the reader in mind.

Opt for designs that are easy on the eyes. Simple things, like consistent headers or even color-coding sections, can make all the difference in guiding your reader smoothly through the manual.

2. Digital vs. Print

When it comes to deciding between a digital or printed manual, think about what your users truly need and how they intend to use the manual.

If you're leaning towards a printed version, remember its strengths: users can physically hold and flip through it, there's no reliance on gadgets, and for some, it's a top choice when working in the field.

On the other hand, a digital manual brings its own set of perks: users can quickly search for specific info, you can distribute it to a large audience with just a click, and there's room to add interactive features. Not to mention, it's a green choice, kind to the environment.

3. Incorporating Interactive Elements

Going digital with your manual? Make the most of tech's capabilities.

Think about adding multimedia: Imagine users watching a video that clearly demonstrates a tricky procedure or exploring complex models of the product. And don't forget about navigation – a clickable index means users can instantly get to the section they need, all with a simple tap or click.

4. Distribution Strategy

Getting your manual into the right hands is key.

For those printed copies, you'll need to plan for things like how to ship them, where to store them, and the best ways to handle them.

Going digital? Look into distributing through your company's intranet, setting up a special website, or even using cloud storage. And always think about security – make sure only the right people have access, and consider adding password protection.

5. Feedback Loop Establishment

Your manual's never truly "finished" – there's always room for improvement, especially with user insights.

Set up ways for users to share their thoughts, whether they've got suggestions, spotted mistakes, or just want to share their experience. Then, take action based on what you hear, making updates to keep your manual at its best.

6. Regular Updates

Products and equipment don't stay the same, and neither should your manual. As things change – from product upgrades to new best practices – keep your manual up-to-date.

Set regular check-ins to review and update your manual. And when you make changes, use version numbers or add revision dates, so users know they're looking at the latest and greatest.

In closing, crafting an O&M manual is not a one-off endeavor. From its design to its distribution and continuous updates, every step ensures that your manual remains an indispensable, accurate, and user-friendly guide for all its readers.

Step 5: Updating the O&M Manual

An effective O&M manual is not a static document. Instead, it evolves, adapting to new technologies, methodologies, and feedback from its users. Periodic updates ensure the manual remains relevant, accurate, and an indispensable tool for operators and maintenance personnel.

Here's how to approach this ongoing process:

1. User Engagement & Feedback

Users are the best critics. Engage with them periodically to capture their insights.

Analytics: Tools can measure the manual's digital engagement, from access frequency to most-viewed sections.

Direct Feedback: Annual surveys and feedback forms help gather user insights on manual usability and areas for improvement.

2. Performance Metrics

Understanding the tangible benefits of the manual is crucial. Track metrics such as operation downtimes reduced, maintenance errors decreased, and safety incidents avoided post-manual implementation.

3. Training and Workshops

Whenever updates are introduced, it’s essential to guide users through the changes. Organized training sessions and feedback workshops can clarify doubts and gather real-time feedback.

Benchmarking & Industry Standards:

Stay updated by comparing your manual against prevailing industry guidelines. Engaging in mutual reviews with industry peers can offer a fresh perspective and keep the manual aligned with best practices.

4. Scheduled Revisions

Regularly revisiting the manual ensures its relevance. Set a review calendar, and always clearly mark updated versions with revision dates or version numbers.

By actively seeking feedback, monitoring its impact, and periodically benchmarking against industry standards, you ensure your O&M manual remains both current and effective.

Wrap Up

The realm of Operations & Maintenance manuals, though often overlooked, is integral to the backbone of many industries. Through this article, we've highlighted their indispensable role in optimizing operations, reducing errors, and ensuring that crucial knowledge isn’t lost amidst rapid changes.

Beyond just grasping the benefits, we've delved deep into the key components that make an O&M manual truly effective.

A well-crafted O&M manual stands out as more than just a document—it’s a catalyst for continuous learning, a beacon guiding teams toward operational excellence, and a repository that captures decades of collective wisdom. As industries evolve, technology surges forward, and operational dynamics shift, having a comprehensive, living O&M manual becomes even more crucial.

For organizations and professionals alike, it's essential to recognize the value of these manuals. By investing time and resources into creating and regularly updating them, you not only ensure smoother operations today but also lay down a legacy of knowledge for tomorrow.

Looking to create the best Operations & Maintenance manuals? Give Helpjuice a spin. Dive into their world of seamless documentation with this FREE 14-day trial.