Imagine you're asked to describe what your company does. Naturally, you might detail your standout products, exceptional services, and the unique value you offer. This is usually the kind of answer people expect – a succinct and compelling elevator pitch.

Yet, this is just the tip of the iceberg. Beneath the surface, your organization is a complex machine with countless "moving parts," a phrase that may seem cliche but aptly captures the intricate reality. Each of these parts represents an internal process, vital cogs that keep the business running smoothly and efficiently.

In essence, the heart of your organization's success lies in these internal processes. Each internal business process helps to shape your company's identity and its capacity for growth. Therefore, continuous improvement of these processes is not just a good practice but a crucial strategy for your business's health and success.

By refining and improving these internal processes, you're not just keeping things as they are; you're driving your company toward greater efficiency, adaptability, and overall excellence. And that's why understanding and improving your internal processes is one of the most impactful investments you can make in your organization's future.

What is an Internal Process?

An internal process is a series of steps or actions that take place within an organization to achieve specific goals without the involvement of external partners. These processes are crucial for accomplishing day-to-day tasks and identifying areas for improvement.

Understanding internal processes can help clarify team members' responsibilities and enhance your company's efficiency and productivity. These processes can range from simple tasks like managing purchase orders to more complex ones like adhering to federal regulations.

Internal processes can be categorized as formal or informal:

- Formal Internal Business Processes are those that are standardized, documented, and routinely followed in a uniform fashion. Teams usually focus on formalizing processes that are most crucial to the business’ core operations, such as employee and customer onboarding, safety training, and team-specific procedures.

- Informal Internal Business Processes are not standardized or documented, and can be approached in myriad ways while accomplishing a singular task. For example, team members don’t always need to use a specific channel or follow certain protocols every time they communicate with one another.

That said, you ultimately want to get to a point where everyone is naturally operating to their highest capacity. Ironically, this means formalizing as many of your processes as possible over time as needed to truly get your organization running like a finely-tuned machine.

How Can Improving Business Processes Benefit Your Company?

Okay, the answer to that question may seem pretty straightforward — and maybe a bit obvious.

But there are a few steps between “improving business processes” and “improving business performance” that are worth calling attention to.

1. Uncovers Major Roadblocks

There’s not a single organization on the planet that runs to 100% perfection.

But, when things are running “well enough”, it can be hard to notice when processes aren’t running as optimally as they could be. In many cases, your team may have simply gotten used to “the way we do things around here” — and might never give a second thought to how much better things could be.

(This is especially true of informal processes. Due to their inconsistent nature, it can be near impossible to say whether a process is or isn’t working as well as it could be — or to identify when certain processes just aren’t working at all.)

Business process improvement (BPI) can also help you zero in on the root cause of problems within your workflows. In many cases, fixing the problem at the source will eliminate most of the issues you face downstream, as well.

2. Minimizes Error (and the Impact of Errors)

Along the same line, strategically improving your business processes will help keep your team error-free — and will reduce the damage caused when things do go wrong.

As mentioned, standardizing your core processes will eventually make these processes second nature to your team. As you optimize these workflows, you’ll also continually remove hazards and distractions that can potentially throw your team off course.

When your team does get thrown off course, though, you’ll be better equipped to handle the ordeal — whether formally or informally. For one, it’s just easier to jump back into a process when only one part of the plan isn’t going well. Moreover, you’ll likely have developed contingency plans to fall back on should you encounter these issues in the first place.

3. Improves Employee Productivity

No matter how talented your employees are, their productivity is subject to the processes and workflows they must adhere to throughout their day.

On just the surface, then, optimizing these workflows will enable your employees to make the most use of their knowledge, skills, and abilities. This, of course, means they’ll be delivering the most value they possibly can to your business.

(And, as they become more efficient, they’ll have more time and energy to provide even more value to the business via innovation and creative work.)

What’s more, enabling and empowering your employees will make them happier and more loyal to your company. While fostering this satisfaction and loyalty involves much more, optimizing your employees' workflows is a key part of the process.

4. Improves Teamwork and Company Culture

Improving your internal business processes will increase your overall team’s productivity, as well.

Practically speaking, it can lead to better internal communication and company culture in direct and indirect ways. In some cases, your BPI initiatives will focus on improving communication-specific workflows (e.g., adding new chat tools, refining contact protocols, etc.). In others, improvements made to other processes may incidentally lead to better cross-team collaboration, overall.

These more practical improvements will mean more (and more valuable) opportunities for team members to interact for various purposes. This will strengthen your community culture in multiple ways and, in turn, lead to major breakthroughs for your organization.

5. Optimizes Use of Resources

Friction-laden processes don’t just hold your employees back.

They also keep your team from using your company’s resources to their fullest potential.

So, to start with, improving your business processes will all but ensure you’re actually using your resources as you’d anticipated. At the very least, you’ll be minimizing the number of resources wasted.

Better yet, you’ll be allocating resources more effectively — leading to operational improvements that allow your team to squeeze even more value than you’d anticipated. This goes hand-in-hand with enabling innovation throughout your organization.

6. Enhance the Customer Experience

Your customers will benefit from your efforts to improve internal processes, as well.

Obviously, working to improve your customer-facing processes (e.g., sales engagements, user onboarding, customer service, etc.) will have a direct impact on their overall experience with your brand.

Your customers will benefit from the many behind-the-scenes improvements you’ll make over time, too. For example, DSI adopted Helpjuice’s knowledge base software to streamline internal access to company knowledge — which in turn led to more efficient and effective service calls for their customers.

"Since using Helpjuice, we've seen a lower AHT for our calls. Our pilot agents are able to find information in a timely manner. Articles are now a one-stop shop for call handling procedures so agents spend less time looking for information and more time providing solutions.”- Reagen Read, DSI Training Specialist/KB Admin

7. Increases Profit

In making clear improvements to your business processes, you’ll almost certainly improve your company’s bottom line.

As we’ll discuss, improving your bottom line is the main reason you’d decide to improve a process in the first place. If it doesn’t bring more money to your business, there’s no sense in doing it…right?

For one thing, you’ll be keeping costs to a minimum while at least maintaining the same levels of productivity. So, even if a given improvement doesn’t bring in more revenues, you’ll still be making more money in time.

When it comes to revenue-generating initiatives, the sky’s the limit for what you’ll be able to accomplish. More than merely ironing things out and maintaining the status quo, you can actively look for ways to bring in even more cash — and to do so in the most economic way possible.

Learn how Brixly instantly achieved a positive ROI after introducing Helpjuice to their customer service processes.

Business Process Improvement Methodologies

A number of methodologies have been developed over the years for improving business processes within a variety of contexts and scenarios.

Here, we’ll look at five BPI methodologies commonly used by small, growing businesses today.

(Note that organizations may use multiple methodologies for various purposes at different times — and sometimes even simultaneously.)

Six Sigma

Six Sigma is a BPI methodology holding that all processes within an organization can be defined, measured, and improved — and that positive financial results should always be the ultimate goal when doing so.

Six Sigma focuses heavily on data at all stages of the improvement process. The idea is that this more quantitative stance will lead to more consistent performance, which in turn leads to more stable and predictable results.

Six Sigma offers two separate processes for improvement:

- For new processes, DMADV: Define, Measure, Analyze, Design, Verify

- For existing processes, DMAIC: Define, Measure, Analyze, Improve, Control

In both cases, the 6M’s of Six Sigma drive all efforts to improve performance in a comprehensive, cohesive manner.

Agile

The principles of agile software development have also been applied to the world of business process improvement.

Essentially, the agile approach to BPI involves:

- Making iterative, prioritized improvements to a given process

- Using collaborative sprints to make singular, laser-focused improvements to the process

- Quickly pivoting to higher-priority tasks as they become known

The idea behind agile is to make the most immediately practical and impactful improvement possible at any given moment. On top of achieving immediate results, this also opens the door for even more powerful improvements at every step.

Theory of Constraints

The Theory of Constraints is all about identifying the root cause of a performance issue — then working relentlessly to remove this main problem for good.

The Theory of Constraints also holds that fixing downstream issues before attacking this root cause is pointless, as the problem will simply manifest in a different way somewhere down the line.

The foundation of this methodology is that there will always be bottlenecks within your operations, and that identifying and fixing them is an ongoing, never-ending task. As such, the Theory of Constraints follows these steps:

- Identify the root cause of the problem

- Exploit the root cause using your current resources

- Subordinate related tasks and processes to support improvement initiatives

- Elevate the issue as a priority for investing more resources, as needed

- Repeat this process to make further improvements to your operations

Lean

Based on the practice of lean manufacturing, lean BPI aims to minimize waste, and to ultimately squeeze the absolute most value possible out of every resource used.

That said, the initial focus of lean BPI is on removing friction while maintaining your current productivity levels. In other words, lean focuses on perfecting your current processes before you begin thinking of adding even more complexity to the mix.

There are a number of subsets to lean BPI, such as kaizen, PDCA, and 5S. Despite their variations, each methodology adheres to the principles of lean operations:

- Identifying the most valuable procedural improvement to make

- Mapping the flow of resource usage throughout the process

- Removing waste while streamlining processes

- Adjusting related operational plans accordingly

- Making further improvements based on performance

Best Practices for Improving Internal Business Processes

While the methodologies discussed above differ in many ways, you probably noticed some considerable overlap between them.

These commonalities are where we can find the foundational best practices for improving your business processes. Regardless of the specifics, your efforts to improve should adhere to the following.

Be Focused & Committed

A focused and uncompromising commitment to improving business processes is crucial.

Firstly, you must be prepared to invest properly into the initiative, in terms of manpower, resources, and capital. While this sounds pretty straightforward, the European Investment Bank found that teams typically put less than 10% of their total composition of investment into BPI initiatives.

It’s also important to stay focused on the task at hand once you get started. Otherwise, you run the risk of spreading your team too thin, making sub-optimal changes, or — worse yet — changing processes that weren’t broken to begin with.

Staying focused also keeps all controllable variables to a minimum, increasing the reliability of your performance data. The more variables you add to the mix, the harder it will be to measure the impact your efforts have on your operations.

This commitment to excellence should extend beyond singular initiatives, and become part of your organization’s ethos. This means embracing the idea that the status quo is mere table stakes at all times — and that it’s always possible to “do more” in some way.

…But Keep Tunnel Vision In Check

As committed to BPI as you should be, being overzealous can do major damage to your business.

This overzealousness can manifest in a number of ways, such as:

- Focusing too heavily on symptoms while ignoring the root cause

- Investing too heavily into a minimum-impact initiative

- Creating change for the sake of change

In any case, you’ll be wasting a ton of manpower, time, and money for minimal results. Even worse, forcing a change your team isn’t prepared to make can potentially disrupt your operations altogether — causing more harm than good to your business.

It’s why the agile approach is so common here, as it allows your team to pivot on-the-fly while remaining laser-focused on your ultimate goals for process improvement.

Be Data-Driven

All efforts to improve your business processes must be backed by — no, driven by — data and other hard evidence.

This means using data to:

- Identify and prioritize areas in need of improvement

- Create plans for improving the process

- Gauging the effectiveness of your efforts, and making plans for the future

Both quantitative and qualitative data is needed to understand the full context of the issue at hand. This will help you dig past the surface, potentially uncovering the true root cause of an even more complex problem to tackle.

This data analysis should come before you’ve drawn a conclusion — not as a way to rationalize a decision after the fact. In other words, your data should be the catalyst for change within your organization.

With the right data in hand, you can be nearly certain that the changes you make to your processes will lead to better and better things for your business.

Invest Strategically in Automation and Other Tools

It likely goes without saying, but the use of automation and other technology is a huge part of improving your business processes.

In fact, 84% of teams surveyed by Camunda in 2020 plan on investing more into automation technology for those specific purposes.

Source

As shown above, organizations typically invest in technology to:

- Automate routine processes

- Centralize processes and information across platforms

- Maximize visibility of data and processes for all stakeholders

The following, then, are all but essential to your BPI efforts:

- Project management tools like Notion or Trello to keep improvement efforts focused and on-track

- Internal communications tools for real-time and asynchronous collaboration and messaging

- Knowledge base software for immediate reference and documentation of processes

Steps for Improving Internal Business Processes

While we touched on some of the key steps for improving business processes when discussing methodologies, let’s now take a more comprehensive look at what these all entail.

1. Prioritize Areas to Improve

Your first order of business will be to identify:

- Which business processes are in need of improvement, and

- Which of these areas should be your top priority

A holistic approach is critical here, as it will keep you from experiencing the dreaded tunnel vision we discussed earlier.

On top of considering the severity of the myriad issues you’re facing, you also want to think about:

- Which problem you’re most equipped to handle

- The cost of fixing each issue you’ve discovered

- Which problems, when fixed, will lead to the best outcomes for your business

Similarly, consider the downside of not taking action — on your operations and on your business.

Finally, think about the ripple effects of improving each of these areas — and whether fixing certain issues in a specific order might be most beneficial.

Remember:

None of this happens in a vacuum.

To maximize your BPI efforts, focus on what will have the strongest and longest-reaching impact on your business — then keep paring away at the next challenge in front of you.

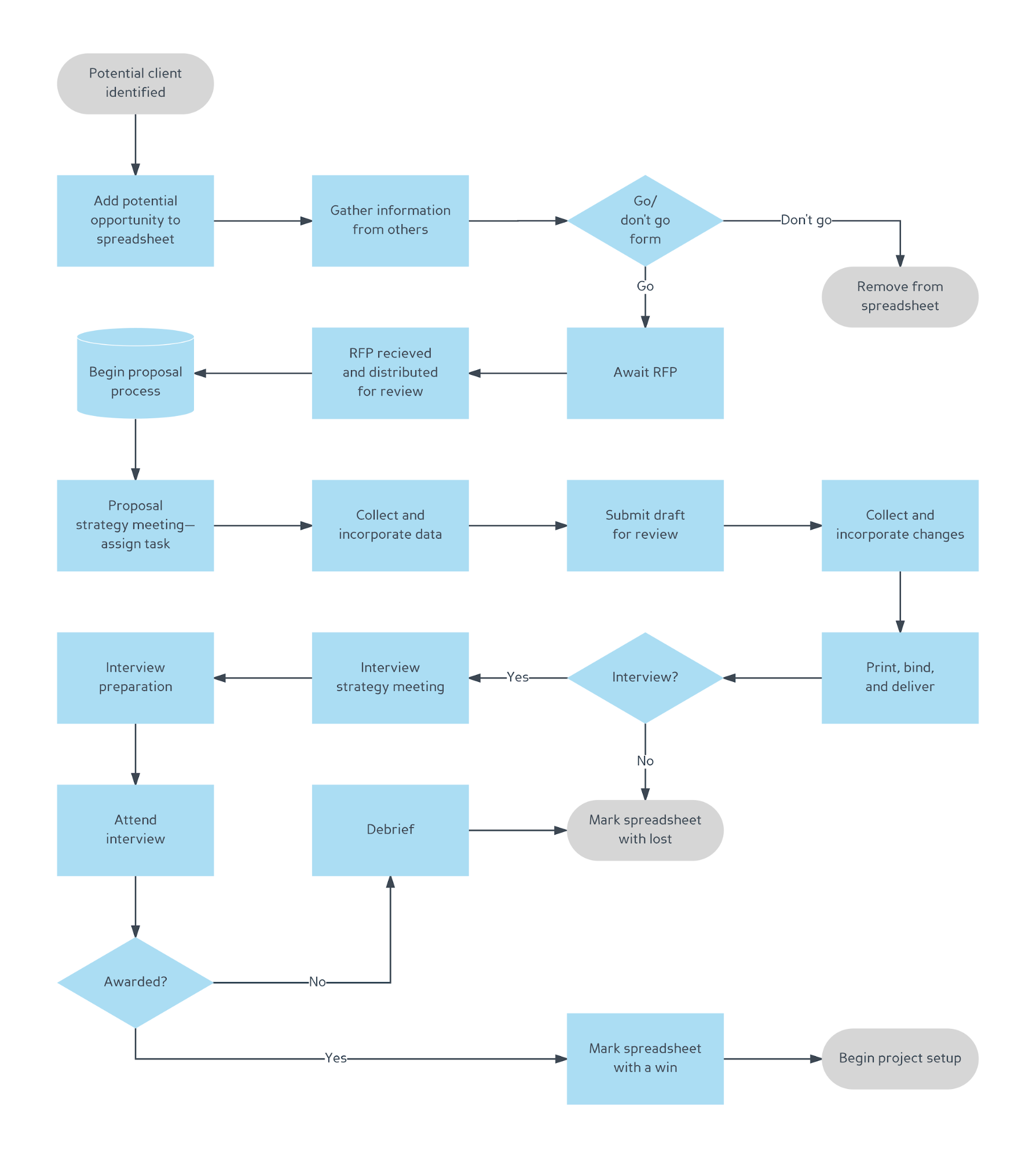

2. Map & Document Your Current Processes

Ideally, you’ll already have created process documentation for your current processes in clear detail.

If not, now is the perfect time to begin mapping your processes.

For informal processes, you'll need to create documentation from scratch. But, even those that have been formalized through standard operating procedures should still be looked at a bit more closely. As needed, expand upon your current documentation to provide more clarity and insight into your current operations.

This documentation should include:

- Step-by-step details of the process

- A list of the team members and resources involved

- Diagrams, illustrations, videos, and other multimedia illustrating the process

You’ll also want to know whether the process looks the same in practice as it does on paper which can be done by:

- Analyzing employee performance data

- Collect feedback from team members

- Observing processes in action to determine whether or not your documentation matches reality

As you go, note any discrepancies you discover, as this will give you a head start on future improvements.

3. Analyze & Assess Your Current Processes

Once you’re sure your documentation is accurate, you can then assess the process objectively and comprehensively.

Start by looking at things from the top down. Ask yourself:

- Is performance matching expectations?

- How wide is the gap between each?

- Are there any glaring issues noticeable from this vantage point?

(Note: You may already have this background info in hand from previous steps.)

From there, you’ll switch to a bottom-up approach. Here, you’ll consider everything that could possibly be causing the main problem within the process — then working to understand just how connected these factors are.

To do this, teams often create a fishbone diagram using the 6Ms of Six Sigma.

Source

Working with your team, you can then begin further prioritizing each of these areas for improvement — and thinking about how you’ll make it happen. Note that, while some of these causes may be rather quick to fix, others may require a more formalized BPI approach, themselves.

(Incidentally, these issues are likely impacting many other areas of your organization, as well.)

4. Set Clear Goals

Now, you’ll need to set goals for your BPI initiative.

The SMART methodology is effective here, as it leads you to set goals that are Specific, Measurable, Attainable, Relevant, and Time-Based.

Using the above example, you can transform the basic goal of “decreasing invoice errors” by answering the following questions:

- Specific: Decrease invoice errors by how much? (Amount or percent?)

- Measurable: How will you measure the number of errors? What’s considered an error?

- Attainable: Can you do what’s needed to reduce invoice errors given your circumstances?

- Relevant: How will reducing invoice errors impact your operations and your business?

- Time-Based: How long should it take to reduce invoice errors by the intended amount?

On top of giving you clear goals to strive for, being this comprehensive will help you assess your improvement efforts over time.

5. Plan & Implement Change

Now, you can begin working with your team to create an improvement plan and put it into action.

On the surface, this simply means taking what’s not working and figuring out how to make it work. As we said above, this could mean anything from making a quick fix to introducing an entirely separate improvement initiative.

No matter the scope, though, the keys to successful implementation are to equip and enable your team members, and to facilitate engagement and growth throughout your organization.

(In short: Implement strategic change management.)

Depending on the situation, enabling your team may involve:

- Giving them additional time and resources to improve

- Introducing new technology to your tech stack

- Providing appropriate training and development sessions and other learning opportunities (for example, making use of communities of practices)

You might need to let your team practice implementation of the new process before actually doing so. Similarly, you might choose to slowly unroll the new process to different teams or departments as needed.

(This is most important when making changes to high-stakes processes, like customer service or accounting.)

Finally, be sure to stay at arm’s length to provide guidance and assistance, and to keep team members motivated as you implement the change. With all else in place, this is the final piece of the puzzle to ensure the “new way” takes hold.

6. Review, Solidify, & Document Procedural Changes

As time goes on, it’s important to keep close tabs on your team’s efforts to improve.

Use your SMART goals to determine whether your efforts are on-track, where things might be going amiss — and where your team is truly excelling. Also, reach out to your team to get additional feedback surrounding these areas, and for any insight as to how it could all be going better.

Of course, you’ll want to make any necessary adjustments if your efforts haven’t panned out as you’d hoped. Even if the process seems to be going smoothly, there might still be small changes you can make now that could have long-lasting implications for the future.

Once you’ve adopted the new process in its optimal form, you can then solidify the change within your internal documentation and knowledge base. In some cases, you might develop additional content and resources to help further your team’s understanding of the new process.

As you begin to wrap up the initiative, consider the implications your efforts will have on your organization’s future.

Consider:

- How you can improve the process even further

- How other processes have been enabled by your efforts

- Where you should shift your focus to next

From there, it’s on to the next business process in need of improvement.

Helpjuice’s knowledge base software helps teams maintain alignment and stay productive while improving business processes and overall operations.

Want to learn more? Schedule a demo with Helpjuice’s team today!