Looking to streamline your workflows, remove inefficiencies, and supercharge your business operations?

It all starts with a process improvement plan.

In this article, we’ll explain what a process improvement plan is, why they’re important, and what goes into creating an effective plan that guarantees a positive outcome for your business.

What is a Process Improvement Plan?

A process improvement plan (PIP) is a strategic document detailing everything you’ll need to know and do as you make foundational changes to your workflows and processes.

Process improvement plans provide key background information and data regarding the processes that are currently in place. Along with the team’s current performance metrics, the document will also explain why a procedural change is necessary at the present moment.

From there, the document will define the goals of the initiative and the solution to be implemented — followed by an in-depth plan for said implementation. The plan can also include a schedule for implementation and a method for monitoring progress, as well as any supporting documentation to help further your team’s efforts.

Process improvement plans are integral parts of both business process improvement and business process re-engineering. No matter the process in focus, your process improvement plan should act as a roadmap guiding you toward your goals — and bringing you one step closer to procedural optimization.

Why a Formal Process Improvement Plan is Crucial

While some organizations may take an ad-hoc approach to improving processes at times, taking the time to create a formal process improvement plan will always be better for your business.

For one, it allows you to gain a more comprehensive and cohesive understanding of the issue at hand. This will help you identify the root cause of the issue, instead of focusing on just one of many symptoms of the problem.

(Without taking this step back, you’ll likely end up making mere surface-level changes that don’t actually address the full extent of the issue — which will inevitably lead to even more problems somewhere down the line.)

Creating formal process improvement plans also allows you to better prioritize your efforts by focusing on the processes that have the most impact on your business. That way, you don’t end up investing too much time and money making changes that don’t really move the needle for the company.

On that same token, creating a strategic plan for improving a given process ensures you’ll be as efficient and cost-effective as possible when doing so. In contrast, a haphazard approach to process improvement will likely require at least some guesswork, trial-and-error, and other rather inefficient approaches.

Finally, a formal process improvement plan helps to establish accountability for improvement initiatives. By clearly defining the objectives, responsibilities, and timelines for improvement, a formal plan ensures that everyone in the organization is on the same page and working towards a common goal.

(This is crucial not just for immediate, practical purposes, but also to continue fostering a culture of ongoing learning, growth, and engagement throughout your organization.)

No matter how simple a procedural change may seem, there’s just too much at stake to not take a formal approach to improving it. Take the time to make a plan of attack; it will always be worth it.

Process Improvement Plan Methodologies

There are a number of methodologies you might choose to follow when developing your process improvement plans.

Some key examples include:

- Lean Methodology aims to identify and eliminate wasteful tasks and use of resources throughout a given process. The goal is to make processes as streamlined as possible, while using the absolute minimum amount of resources necessary.

- Six Sigma Methodology focuses on improving quality and reducing defects by eliminating sources of variation throughout a process. The steps involved in Six Sigma methodology are Define, Measure, Analyze, Improve, Control.

- Plan-Do-Study-Act (PDSA) Methodology is a cyclical model of continuous improvement that can be implemented in most operational contexts. As the name suggests, it’s a four-step process of planning, making iterative changes, reflecting on results, and codifying the change within your workflow documentation.

For a more in-depth look at these and other PIP methodologies, check out our article on improving internal business processes.

Effective Process Improvement Plans: Best Practices

Before getting into the step-by-step process of creating an improvement plan, let’s go over some key best practices to follow at all times when creating them.

Align with Your Business Goals

Above all else, you need to be certain that the changes you make align with your business goals — and that they have a substantial and positive impact on your company as a whole.

Put another way, you don’t want to make any changes to your processes that will pull your company off-track in any way. While the importance of financial growth is obvious enough, you also need to consider how a change may impact your company culture, employee engagement, or customer loyalty.

Keeping this alignment top-of-mind will actually help you maintain a strategic approach to process improvement (as opposed to making a “quick fix” in the heat of the moment — which typically won’t work out for the best).

Essentially, you should always be thinking of the “bigger picture”. Before making any systemic changes to your processes, make sure the change you make is the move that will bring you closer to your goals than ever before.

Be Specific

Specificity is vital when planning to make procedural improvements — and when documenting said plan in writing.

Firstly, you must be as specific as possible when identifying the process to be improved. This will help you pinpoint the exact thing that needs to change, and will guarantee that you’re focused on the root cause of the problem.

(In contrast, being too broad here may cause you to make sweeping changes that are ineffective, superfluous, or both.)

You’ll also need to be specific when defining how you’ll make the planned improvement. This is key to remaining lean while also investing the manpower and resources needed to succeed.

Finally, you’ll need to define your intended goals and outcomes — and the rationale behind them — clearly and specifically. As we’ll discuss, this will keep you focused on the right tasks throughout the initiative, and also help you assess your efforts once the new process is in place.

Be Data-Driven, Objective, & Critical

The most effective process improvement plans are those that are backed by hard data, allowing teams to take a more objective and critical approach to the initiative.

With the right data in hand, there will be very little question as to what process needs to be improved — and how so. Moreover, analyzing comprehensive data sets can help you uncover hidden problems your team may not have been aware of.

Becoming more data-driven is key to removing biases during the planning stage and minimizing resistance to change once the plan is in place. Without clear evidence that a given change will improve operations, teams can easily backslide into the “old way of doing things” — in spite of all the frustration the old way may cause.

Involve All Stakeholders

Making even the slightest changes to your processes can impact a number of individuals, both within your organization and outside of it.

Involving these stakeholders in process improvement planning, then, is essential.

You’ll of course want to involve those who are directly impacted by the change — that is, those responsible for carrying out the process in question. These individuals will have hands-on knowledge of what needs to improve, and will likely have a number of practical solutions in mind for the team to consider.

Managers and team leads will have a clear understanding of the team’s capacity for making a change, along with the impact said change will have on the team’s overall operations.

When needed, executives can step in to ensure a process improvement plan aligns with the company’s business goals and overall vision for the future.

Finally, consult any third-party entity that will be impacted by the change, such as your suppliers, your vendors, or your customers. This will at least help you stay transparent and maintain open lines of communication — and it can potentially lead to major breakthroughs that wouldn’t have happened had you kept everything in-house.

Steps to Creating an Effective Process Improvement Plan

As we’ve said, developing an effective process improvement plan can be a rather involved initiative.

Involved — but very much worthwhile.

So, without further ado: The eight steps to creating an effective process improvement plan.

1. Define the Process to Improve

Your first order of business is to identify the specific process or workflow to be improved upon.

Some key examples:

- Customer service request intake

- Marketing-to-sales lead handoffs

- New hire form submission

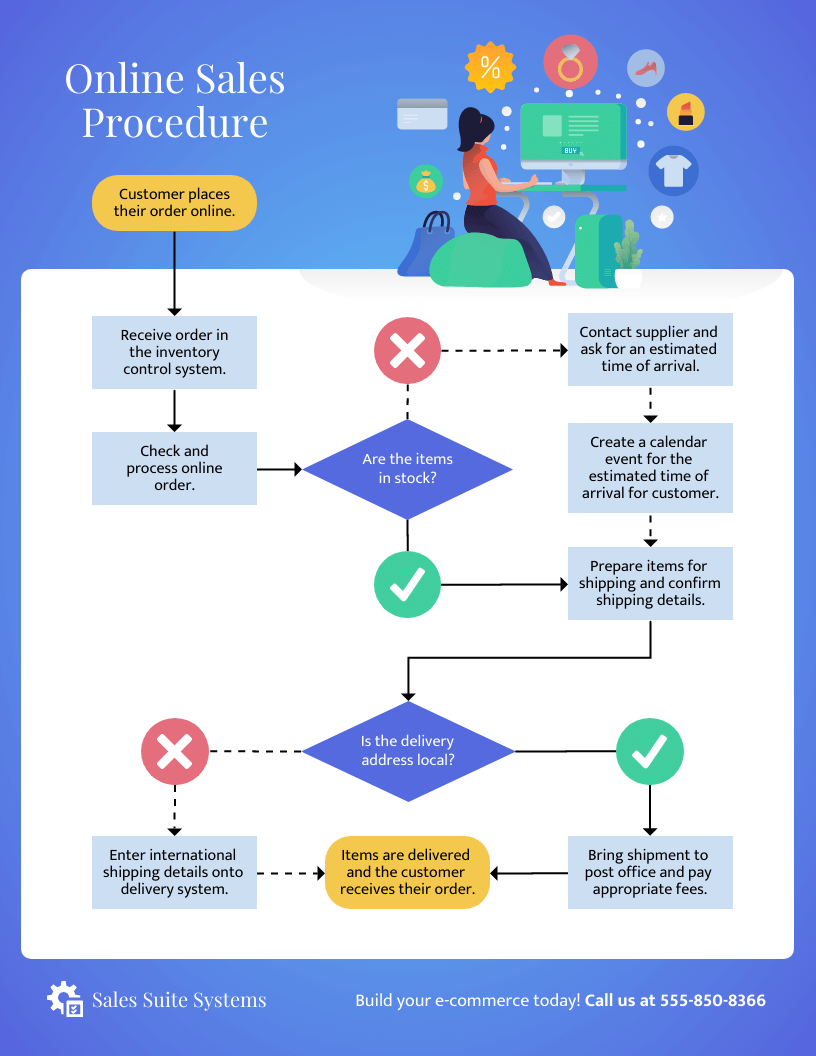

Be sure to include any documentation that will help map the parameters of the process. In some cases, it may be necessary to define what the process doesn’t involve to avoid making unnecessary changes.

While you’ll eventually provide more details regarding the initiative, you can set the stage here by giving an overview of what’s to be improved, why doing so is important, and what your intended goals are. With a clear vision of success in place, your team can focus on making the specific changes needed to make it a reality.

2. Identify Stakeholders (and Their Roles)

As we said, all stakeholders should be involved in the improvement process to at least a certain degree.

For each initiative, you’ll need to define who these entities are, and the role they’ll play in improving the process in question.

Again, the main roles to consider include:

- The ground-level employees who will be directly impacted by the change

- Managers and team leads who will spearhead the initiative and facilitate procedural change

- Executives who will oversee the business end of the initiative

- Third-party entities who will be impacted by the shift in procedure

Once you identify these entities, you might consider forming a committee with representatives from each group to help move the initiative forward. This will lead to more and better insights and idea generation during the planning phase — and will allow you to stay transparent as you implement improvements to your processes.

3. Analyze the Current Process

At this point, you can start taking a closer look at the actual process to be improved.

As things stand, you want to be clear on what’s working well within the process — and what isn’t.

Consider:

- Where do bottlenecks tend to occur?

- Where is resource usage and waste highest?

- Where are members of your team typically left idle or waiting?

Once you identify these troublesome spots, go a step further by looking both up- and downstream. In looking upstream, you may potentially uncover a more systemic issue that is the true cause of the problem you’re facing (and many others!). Looking downstream will allow you to see what other processes will be impacted by a given change — and may open the door for more improvements to be made in the future.

When conducting this analysis, remember to use both your collected data and your stakeholders’ collective "know-how" knowledge to form an accurate picture of what the process looks like at the present moment — and how you can improve it moving forward.

4. Create a SMART Goal

Based on your analysis of the process and your current situation, you can create a goal for your initiative that is Specific, Measurable, Attainable, Relevant, and Time-Bound.

Going back to the examples mentioned earlier, you might set the following goals for each respective initiative:

- Reduce customer service intake time by 25% within six months

- Improve MQL conversions by 10% this month

- Reduce hands-on touchpoints during employee form submission by 50% this year

This step is crucial to ensure the improvement you make actually impacts your operations in a positive way — and to give your team a clear idea of what successful implementation of the improvement will look like.

5. Brainstorm and Define Optimal Solution(s)

The next step is to brainstorm solutions to the problem as you begin developing the new process.

As you brainstorm these ideas, you’ll want to pay attention to the following three factors:

- Feasibility and Practicality: Do you have the manpower to implement the change? Does your team possess the skills and knowledge needed to make the new process work?

- Impact: How will the change impact your stakeholders and your business operations? Will additional changes be necessary once the proposed solution is in place?

- Cost: What will it cost (in money, time, and other resources) to implement the new workflow? When will your organization begin reaping the benefits?

6. Create an Action Plan

Once you define the process to be improved, you can start planning how you’ll actually go about implementing the change within your operations.

This can involve a wide variety of steps based on the change to be made.

If automating and optimizing the customer service intake process, for example, you’d need to:

- Install and integrate your helpdesk software of choice — and phase out the old solution

- Onboard and train your customer service representatives

- Introduce your new automated solution to your customers

…and much more.

Detail is important here, as you want to introduce the change as seamlessly as possible — and ensure that it’s the best decision to make from a business standpoint. To this end, you might choose to create a fleshed out business requirements document to go along with your process improvement plan.

7. Implement, Monitor, & Adjust

As you introduce the new process and it starts to become the “new normal”, you’ll want to keep a close eye on how everything’s going.

This should be a team effort involving all stakeholders. While performance metrics and other quantitative data will be a huge piece of the puzzle, you also want to collect more qualitative feedback from those most impacted by the change.

(This is especially true when it directly impacts your customers.)

From there, you can make adjustments to the process as needed over time — as you should always be doing within all areas of your operations in the first place!

In all seriousness, you likely won’t need to create an entirely new process improvement plan as you make these slight adjustments. But, if the “new way” doesn’t pan out the way you’d hoped, there’s no shame in going back to the drawing board.

8. Document, Document, Document

At this point, you’ll have likely documented the new process in text and graphic formats.

Now, you’ll want to start creating additional knowledge documentation that:

- Explains procedural steps in full detail

- Demonstrates the process in action (via video content)

- Provides expert tips and best practices to optimize the process

Zooming out a bit, be sure to adjust any documentation regarding your overarching approach to process improvement planning.

On top of making the new process “official”, documenting it also makes the information more accessible. Marco Armineta, Director of Customer Experience at Valant, explains that documenting new processes with Helpjuice enabled his team “to quickly rollout initiatives that proved difficult with our previous solution, including the ability for customers to rate content and provide free-text feedback.”

Use Helpjuice to Empower Your Process Improvement Plans

Helpjuice’s knowledge base software can supercharge your efforts to improve internal operations at every step of the process.

Brainstorm solutions and create plans for improving processes in real-time with collaborative documentation

Document and share new workflows with employees and other stakeholders in seconds

Make continuous improvements to process and workflow documentation over time

Ready to get started? Sign up for a free 14-day trial of Helpjuice today!